Engineering

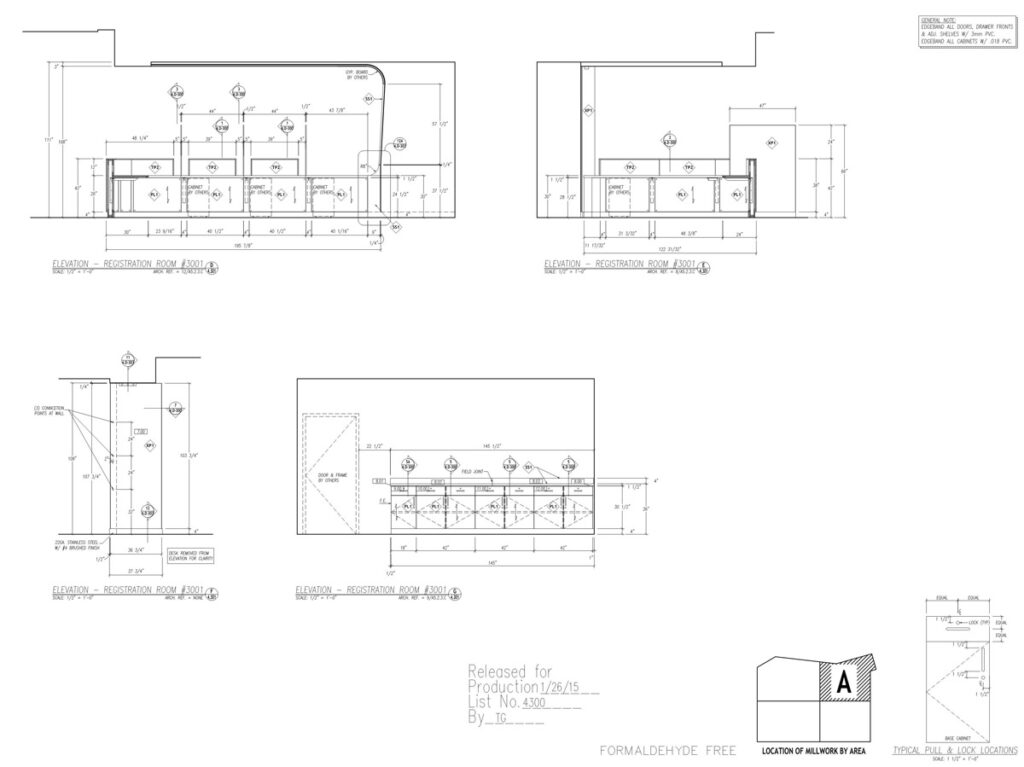

Legere Woodworking employs a number of engineers that perform a multitude of tasks. Their responsibilities include tasks such as researching materials, producing detailed shop drawings based on your architectural specifications and drawings, generating CNC code for our shop floor machinery to allow for the manufacturing of products, and much more. By utilizing AWI standards and best practices, our engineers transform architectural concepts into products that can be manufactured to exacting tolerances, often using 3D modeling to ensure the detailing will work when it reaches manufacturing.

Manufacturing

Legere Woodworking manufactures millwork in our 177,000 square foot state-of-the art manufacturing facility in Avon, CT. All of our shop and field labor is 100% union and we are an affirmative action equal opportunity employer. We produce millwork for projects ranging in size from $300,000 to greater than $12 million. Whatever your millwork needs may be, from cabinetry to one-of-a-kind millwork fabrications, we can build it. Ask us about our FSC® product offerings and how we can help you meet your LEED requirements.

Architectural Metal & Glass

Legere also provides complete services for projects that incorporate architectural metal and glass such as smoke baffles, glass railings in metal channels, stair railings, back painted glass, mirrors, glass marker boards, fully engineered office front systems, and more. Our expertise in scheduling, engineering, and driving project success translates directly to your project success without the headache of trying to coordinate multiple trades and the timing of their installations. By packaging the architectural metal and glass with millwork, we drive the timeline to ensure projects are completed on time.

Installation

Although Legere Woodworking is first and foremost a manufacturer of fine millwork, for 40 years, we have offered installation services for our products. We maintain our own installation personnel for local installations and partner with highly qualified installation sub-contractors beyond our local area. Since we’ve self-performed installations for so many years, we have an intimate knowledge of how our products are installed. This knowledge allows us to engineer products not just for manufacturing, but for a streamline installation as well, allowing us to approach projects with narrow installation windows with the confidence that we can meet the time constraints.